Table of Contents

Introduction

This page is a step-by-step guide to decapping chips using 70% nitric acid with a preheated chip. Results should be good enough for live analysis.

It is assumed that the reader is familiar with standard lab safety procedures; please do not attempt this if you do not have adequate experience!

Photos courtesy of Andrew Zonenberg unless otherwise noted.

Preparation

For thick packages such as PDIPs, the first step is to drill out a well in the top of the chip, centered over the die. The goal is to get as close to the die as possible without hitting it (or, if you plan to do live analysis, damaging bond wires). Use high speeds to avoid chipping the package; I used an 1/8“ endmill in a Dremel drill press at about 15,000 RPM.

Clean the chip thoroughly after drilling. I used a spray of 70% isopropanol from a syringe with a 25-gauge blunt tip needle.

For other packages, such as TQFPs, no predrilling is necessary.

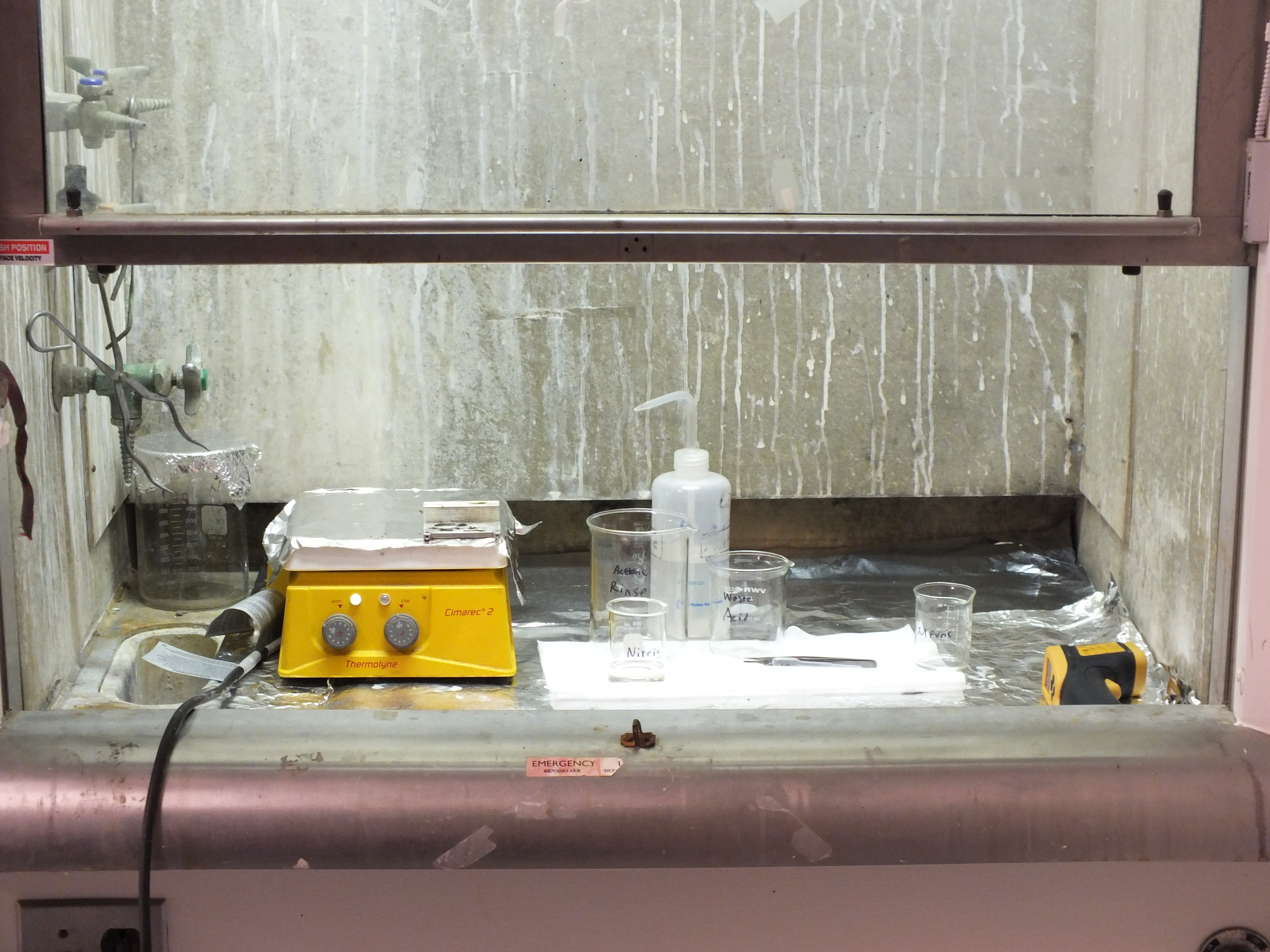

Gather all of the equipment you will be using. The photo below shows one of my lab workbenches; the items of interest are:

- Hot plate for heating chips

- Tray or aluminum foil to protect hot plate from accidental acid splashes

- 70% nitric acid

- Pipette for applying acid to chip

- Large beaker for rinsing chip into

- Infrared thermometer

- Acetone and wash bottle

Nitric acid is quite dangerous so proper safety equipment is a must. I wear a lab coat, splash goggles, and neoprene or Norfoil gloves at all times when doing decapping work. A fume hood is strongly recommended, but given the small quantities of acid being used good cross ventilation may be adequate if your workspace is near an exterior door or window.

Decapsulation

Place the chip in the tray on the hot plate and turn it on. The top of the chip should reach around 130C; large packages with small contact area (such as PDIPs) may need to be placed on a conductive material to ensure even heating; I placed this chip on top of a finned aluminum heatsink.

When the chip is hot enough, place a single drop of acid on the center of the package, or inside the well if it was pre-drilled. Take care not to let any spill onto the pins; this is most critical in small QFP/QFN packages where the leads will be very close to the acid. Large packages such as PDIPs, as well as leadless SMD packages (LGA/QFN/MLF) are significantly more forgiving in this respect.

The acid will appear colorless at first, then as it heats up bubbles will form, sometimes followed by a yellowish-white foam. As the acid finishes reacting the foam will disappear. If the acid shows no reaction or just releases a few bubbles the chip isn't hot enough. In case of very soft epoxy with a fast etch rate, the foam may turn black from package fragments.

Immediately after the foam begins to subside, remove the chip from the tray with tweezers and rinse it with acetone over a beaker. (Be careful not to boil the chip dry; this will cause the fragments to stick to the die.) Use fairly high pressure to dislodge debris.

Return the chip to heat and repeat several times. Make sure the solvent has completely baked off before adding more acid. Eventually, bond wires become visible:

This is a sign that you are getting close. Continue to etch away the remaining plastic, checking periodically to see if the die is fully exposed. Note that there is significant variation in etch speed between different vendors' packaging compounds. In my experience Microchip PICs usually take about 10 drops if skillfully drilled; Texas Instruments 7400 series chips are over five times slower.

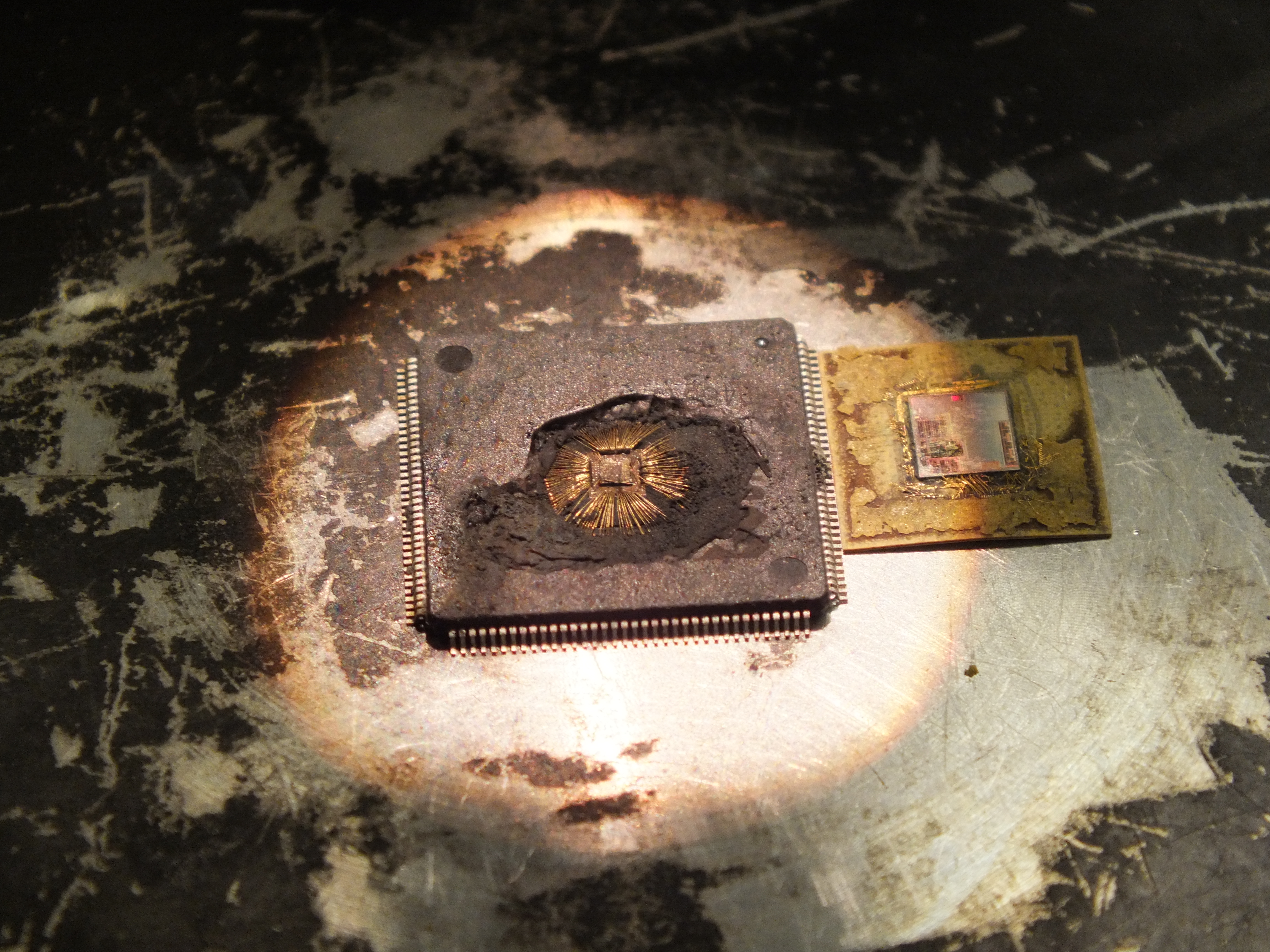

After several drops the chips looked like this:

Cleaning

Most professional shops use ultrasonic cleaners however I did not have one available. I removed residue from the top of the DIP by turning it upside-down and rubbing against a paper towel soaked in acetone, then sprayed the chip off with 70% isopropanol from a syringe. The TQFP required no further cleaning.

The final product:

Results were excellent: no damage to the die, pins, or bond wires.

I plugged the DIP into a breadboard and tested it; it acted somewhat flaky however as I had forgotten to test it prior to decapping I cannot tell if I damaged it, my test circuit was incorrect, or it had been broken to begin with. (The chip had been pulled at random from a pile of scrap parts we had been practicing decapping techniques on, and was not stored in antistatic packaging etc.)