This is an old revision of the document!

Table of Contents

This tutorial will go through the details of what is needed to setup a lapping machine and basic usage.

Setup

A typical basic setup following parts:

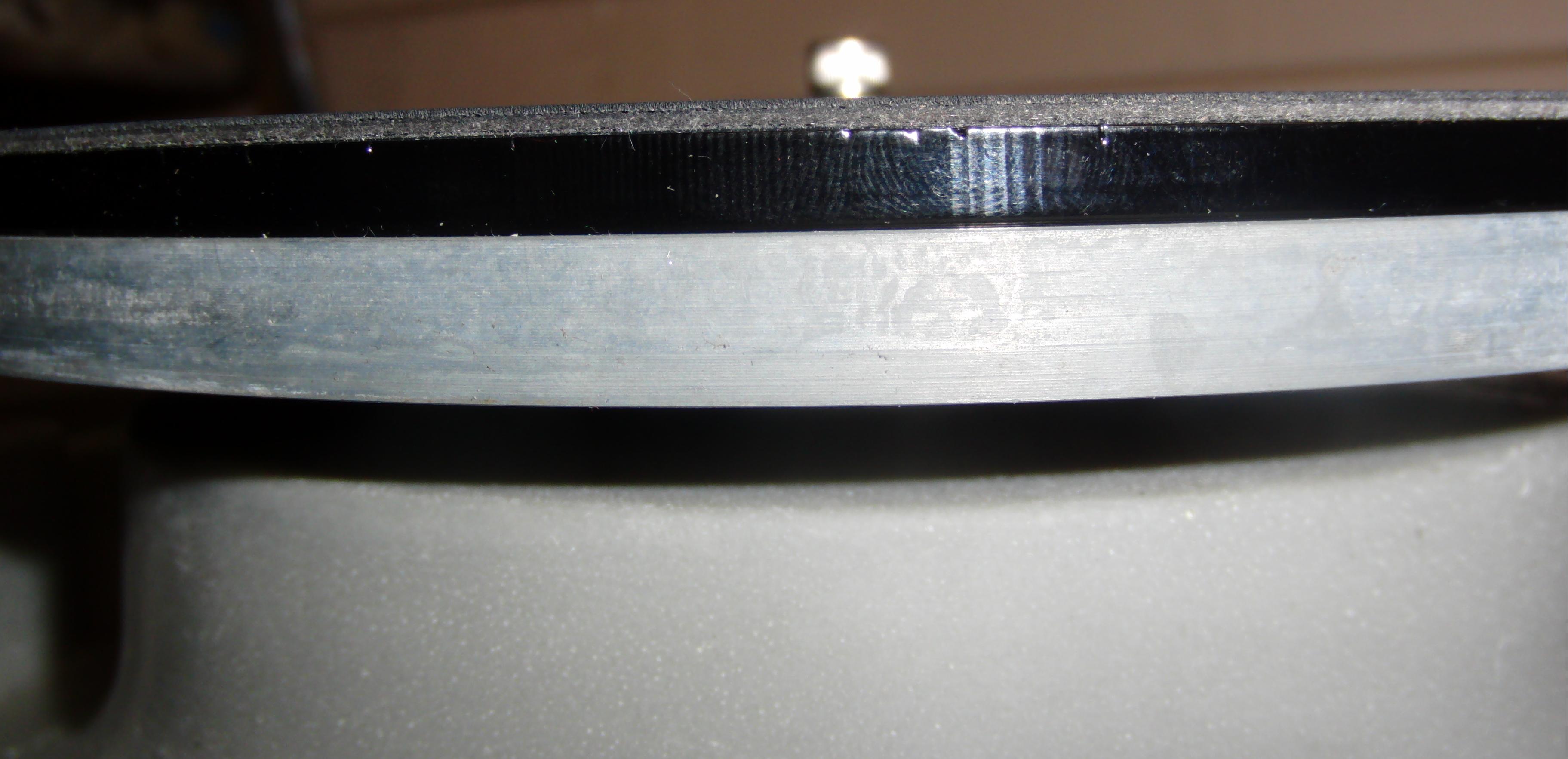

- Master lap: solid aluminum disk that connects to motor shaft. Not necessarily flat but should be radially symmetric

- Backing plate: very flat disk to protect the master lap and provide a flat work surface. I use an MTI EQ-MBP-8-2 although I suspect a plastic sheet would work just as well for most purposes

- Polishing pad: flexible cloth that is the “abrasive”. I use an MTI EQ-PP-8PSA-PC

- York (optional): some machines will have a Y to place polishing jigs

- Jig (optional): holds a sample in place. A finger may suffice

- Machine: essentially a very stable motor and possibly some mounting brackets. I use a very basic unit, a Crystalite CrystalMaster 8

- Motor: provides rotation

- Motor speed controller: most units have variable speed

- Slurry: chemical mechanical polishing (CMP) solution. I use MTI 0.05 um colloidal silica

- Slurry dispenser, typically one of

- Pump: a chemically resistant pump to recirculate solution such as a peristaltic pump. Overkill for most small setups

- Reservoir: hold a large amount of solution that has to be occasionally refilled. I use a small burette

- Collection bottle: since the solution will not be recirculating it has to go somewhere. Let it collect so it can be recycled

My setup:

Note the splash guard to collect slurry as it spins off into the tray below. It feeds through a hole in the bottom to a collection bottle on the floor.

Collection bottle (don't believe everything you read!)

Lapping procedure

Open the stopcock to get solution flowing from the reservoir. A good rate should be between 1 and 3 drops per second.

Tips

Removing an old disc

When I got my machine it had a diamond disk attached to the master lap. I used a heatgun to bring the master lap up to high temperature and then used a punch in the center to bring it out a little. I then took a heavy duty plumbers wrench and ripped it up by rolling it along the diamond disc. While this puts a lot of stress on the master lap the pressure is buffered by the diamond disk and kept even by the flat surface of the plumbers wrench. Once the diamond disc was up the surface was cleaned with acetone. Soaking the disc in acetone for prolonged period may have also worked but would have been slow since the diamond disk was copper/steel backed.