Table of Contents

Why?

According to [Lange,

- Better sealed than plastic. Less moisture gets in to corrode aluminum and fewer contaminants get in during soldering and cleaning

- Easier to combine several components into one package

- Dissipates heat better

- “…better dimensional stability, especially at elevated temperatures.” CTE is less temperature dependent

- Harder to warp

Well then why is plastic more popular? Ceramic costs a lot more. Also CTE of plastic packages is much closer to the PCB. Thus, you are trading a CTE of the die vs the PCB.

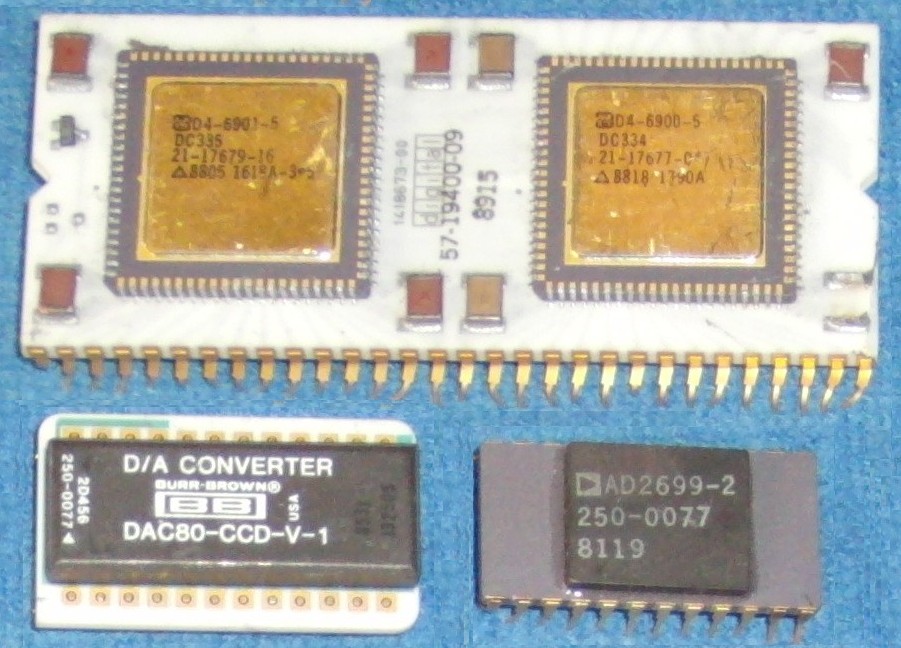

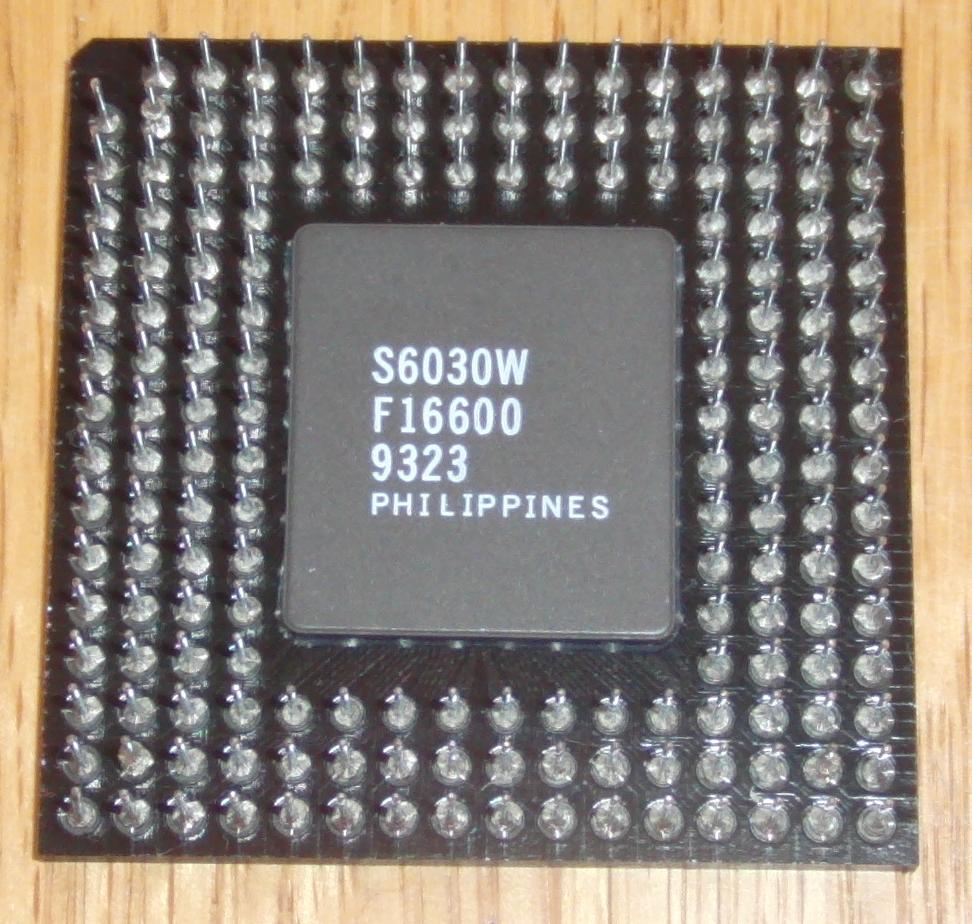

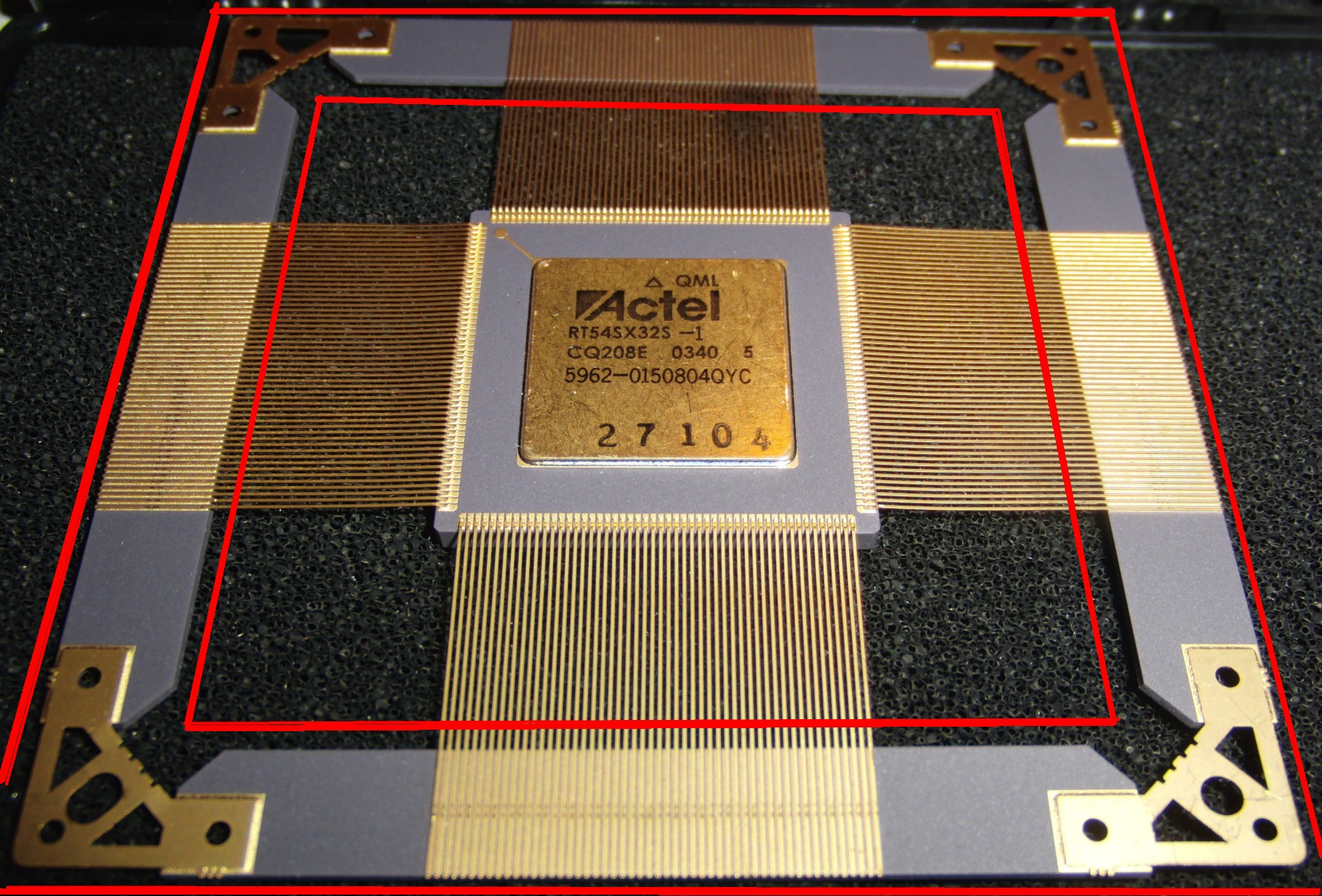

These packages were a lot more popular in the 70/80's but fell out of favor. Not sure if its because plastic packaging improved or ICs became more tolerant but its fairly rare to see ceramic packages today. Most of the high heat dissipation packages are plastic and metal (ex: Intel CPUs). However, because they still provide better sealing than plastic, they still see wide use in aerospace and military. For example, the only modern part in the ceramic collage above is the Actel radiation tolerant FPGA.

General notes

Typical non-ceramic parts include glass seals, metal seals, metal conductors, quartz windows, and electronic components, and the die itself. Co-fired packages place electronic components into the clay before firing. See wiki for more details.

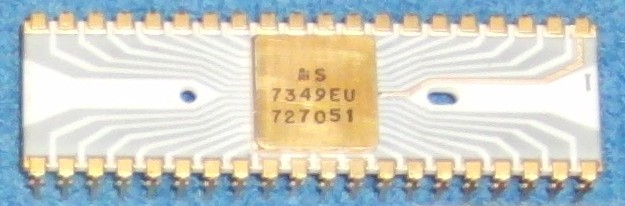

Ceramic packages can be fabricated in multiple layers. According to [Lange, 5] this is done by using “5 to 25 mils thick layers of ceramic tape, each having metalized circuit patterns…These layers are then laminated under pressure.” Example single layer metalization showing through top ceramic:

The DEC chip in the upper left hand corner of the top menagerie is multi-layer but the metalization can is only faintly visible. However, EPROMs, the most common ceramic package one is likely to encounter, are single glass sealed layers with embedded pins.

[Lange, 23] say that alumina is by far the widest used material followed by beryilia [Lange, 24].

Package types

Alumina (Al2O3)

White ceramic packages are usually alumina (Al2O3) with [Lange] mentioning that some are AlN. According to [Lange] alumina packages typically use tungsten or molybdenum conductors and implies that copper conductors aren't used due to firing temperatures. I usually see these metal sealed. As such, see metal for techniques on opening. Alternatively, according to [Etching processes] 1 NH4OH(30%, aq) : 1 H2O2(30%, aq) : 3 H2O @ 80°C eats alumina (unspecified etch rate).

Dark brown packages are 90% alumina [Lange, 24]. According to the composition data below, it seems the other 10% is typically SiO2 and the brown color comes from a few percent of MnO. Due to EPROMs popularity these are the most common ceramic packages one is likely to encounter. Usually glass sealed and so see glass page for info on how to open.

Example substrate composition

Based off of data from [Materials Declaration of 8L CerDIP]. See http://siliconprawn.org/archive/doku.php?id=package:materials for more examples

| Material | % ceramic | % total (ceramic) | % sealing glass | % total (sealing glass) | % package | Appearance |

|---|---|---|---|---|---|---|

| Al2O3 | 88.48 | 62.11 | 3.09 | 0.92 | 63.03 | White |

| PbO | 0.00 | 0.00 | 44.55 | 13.28 | 13.28 | Red-yellow |

| B2O3 | 0.00 | 0.00 | 27.24 | 8.12 | 8.12 | White |

| SiO2 | 2.88 | 2.02 | 5.23 | 1.56 | 3.58 | Clear |

| SnO2 | 0.00 | 0.00 | 11.67 | 3.48 | 3.48 | White |

| MnO2 | 3.39 | 2.38 | 0.03 | 0.01 | 2.39 | Brown-black |

| TiO2 | 1.82 | 1.28 | 4.29 | 1.28 | 2.56 | White |

| Cr2O3 | 1.44 | 1.01 | 0.10 | 0.03 | 1.04 | Green |

| MgO | 0.53 | 0.37 | 1.54 | 0.46 | 0.83 | White |

| Fe2O3 | 1.17 | 0.82 | 0.10 | 0.03 | 0.85 | Red-brown |

| CaO | 0.04 | 0.03 | 1.54 | 0.46 | 0.49 | White to pale yellow/brown |

| Co3O4 | 0.26 | 0.18 | 0.00 | 0.00 | 0.18 | Black |

| ZnO | 0.00 | 0.00 | 0.60 | 0.18 | 0.18 | White |

| Na2O | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | White |

| Total | 100.00 | 70.20 | 100.00 | 29.81 | 100.01 | Light to dark brown? |

Aluminum nitride (AlN)

According to [Rao et al, II-330] these can be found in: thyristors, TO packages, RF packages, heat sinks for car ignition, high power switching modules (ex: IGBT), submounts for laser diodes, MCM PGAs, and QFPs. It may contain 0.5 to 1.5 % Y2O3 by weight as a sintering aid [Lange, 27].

Purple ceramic

Usually metal sealed.

AZ's analysis indicates that the purple is probably something like http://www.washingtonmills.com/products/chrome-alumina/ - mostly alumina with some silica and chromium oxide, plus a few trace elements.

Berylia (BeO)

According to [Rao, II-333] “Power hybrids, bipolar chips, LSI devices, and microwave integrated circuits are often housed in berylia packages.”

[Lange, 24] says that it has 8 to 10 times thermal conductivity of alumina. However, it also has high electrical conductivity at room temperature and is expensive. Additionally, while the finished package is safe, BeO dust is very toxic making it dangerous to manufacture (and noted illegal to manufacture in Japan…). Lange notes that of the impurities on [Lange 26] Si and Mg, the largest, are sintering aids [Lange, 24]. However, because thermal conductivity drops severely below 99.5% the chip even Si is only listed at 1861 ppm (0.1861 %).

Silicon carbide (SiC)

[Lange, 27] says this material is uncommon and costs 20-100 times as much as alumina. “It has good flexural strength and toughness” and has good thermal properties. SiC ranges from clear to dark so unclear what SiC packages look like.

Composite

Its not uncommon for ceramic packages to contain a variety of materials. For example, the left chip is a multi chip module with a Al2O3 base and several purple ceramic subcarriers on it. The right image shows an FR4 base with a ceramic lid (Xilinx XC3090).

Ceramic tie bar

Name Actel calls the ceramic leadframe around the package (highlighted in red above, Actel RT54SX). [Microsemi Packaging FAQs]

Co-fired ceramics

[Minges] says package ceramics are classified into organic and inorganic parts. The inorganic part is made of ceramic and glass while the organic portion is mode of a mixture of a “polymeric binder and plasticizers dissolved in a solvnet”. Glasses are chosen in relation to the organic portion such that “The glass softening point must be high enough to enable organic burnout prior to densification but low enough to ensure sintering to high density”. A temperature difference of 50C to 75C is ideal [Minges, 461].

Low-temperature co-fired ceramic (LTCC)

[[Minges, 461] says typical inorganics are 25% ceramic, 10% borosilicate. Ceramic usually selected based on CTE. Common high CTE choices include alumina, quartz, calcium zirconate, and forsterite. Cmmon low CTE choices include fused silica, mullite, cordierite, and zirconia.

High-temperature co-fired ceramic (HTCC)

[[Minges] says inorganics include 90% alumina, 10% borosilicate. Typical binder is polyvinal butyral.

Die attach

Include:

- Glass (common in EPROM packages)

- Silver solder

- Silver epoxy

- Cynate Esther Paste [Microsemi Packaging FAQs]

References

- Characterizing Integrated Circuit Packaging Materials, Mary Beth Lange: http://scholarworks.sjsu.edu/cgi/viewcontent.cgi?article=1470&context=etd_theses

- Microelectronics Packaging Handbook: Semiconductor packaging By Rao R. Tummala, Eugene J. Rymaszewski, Alan G. Klopfenstein

- Etching processes: http://en.wikibooks.org/wiki/Microtechnology/Etching_Processes|

- Electronic Materials Handbook: Packaging, Merrill L. Minges: http://books.google.com/books?id=c2YxCCaM9RIC&pg=PA461&lpg=PA461&dq=high+temperature+co-fired+ceramic&ved=0CFUQ6AEwAzgK#v=onepage&q=high%20temperature%20co-fired%20ceramic&f=false

- Microsemi Packaging FAQs: http://www.actel.com/documents/PackageFAQ.pdf

- Materials Declaration of 8L CerDIP: http://www.analog.com/static/imported-files/packages/39260738806786CerDIP_8.pdf