Table of Contents

Above: (first row) 8“ Entegris wafer carrier, 6” SEP wafer carrier, (second row) blue tape diced wafer w/ top film cover, simple plastic case for metal mask, red plastic case for mask, wafer held in simple plastic case, green test tube rack for dies in micro-centrifuge tubes, (third row) Fluoroware mask holder, Fluoroware 4“ wafer holder, wafers in plastic case, vacuum sealed wafer.

This page covers ways to store samples, with a focus on after decapping.

General notes

Residual acids will cause corrosion, so make sure to wash well. I've generally not had issues with dies scratching each other, but anything valuable is stored individually.

Die

This section focuses on bare dies as opposed to live decap storage

TLDR

- Small sample

- Individual: 1.5 mL centrifuge tube

- Mass

- Gel pack: sticky surface holds securely in place

- Waffle pack: easier to remove, but less secure for transit

- Large sample

- Membrane box: good option. Slight surface contact, although pretty gentle

- Larger centrifuge tube: space inefficient, but less expensive

- Plastic box: generally not recommended: surface contact damage concerns. Better for live decaps

- Gel pack: generally not recommended: large area makes hard to remove

Centrifuge tube

mcmaster preferred solution for general storage

Size: Most dies are small, say less than 4 mm. Micro-centrifuging tubes work well and can be put into racks or small cabinets. Typically I put dies in 1.5 mL tubes but use 5 mL tubes for larger samples. Over that (uncommon) I'll typically used more specialized storage such as pillowstat boxes or sticky films (see later sections). Note that 0.5 mL look the same as the 1.5 mL tubes but have less volume inside, don't buy them.

Label: I typically wrap a Brother label around them. Prefer specifically the Brother PT-2030 (over say the PT-2730). In margin: short mode it prints the label justified to the right with a leader on the other side. This makes it easy to wrap around tubes and still get nice centered text. Messy handwriting aside, permanent marker labels can rub or be washed off with acetone.

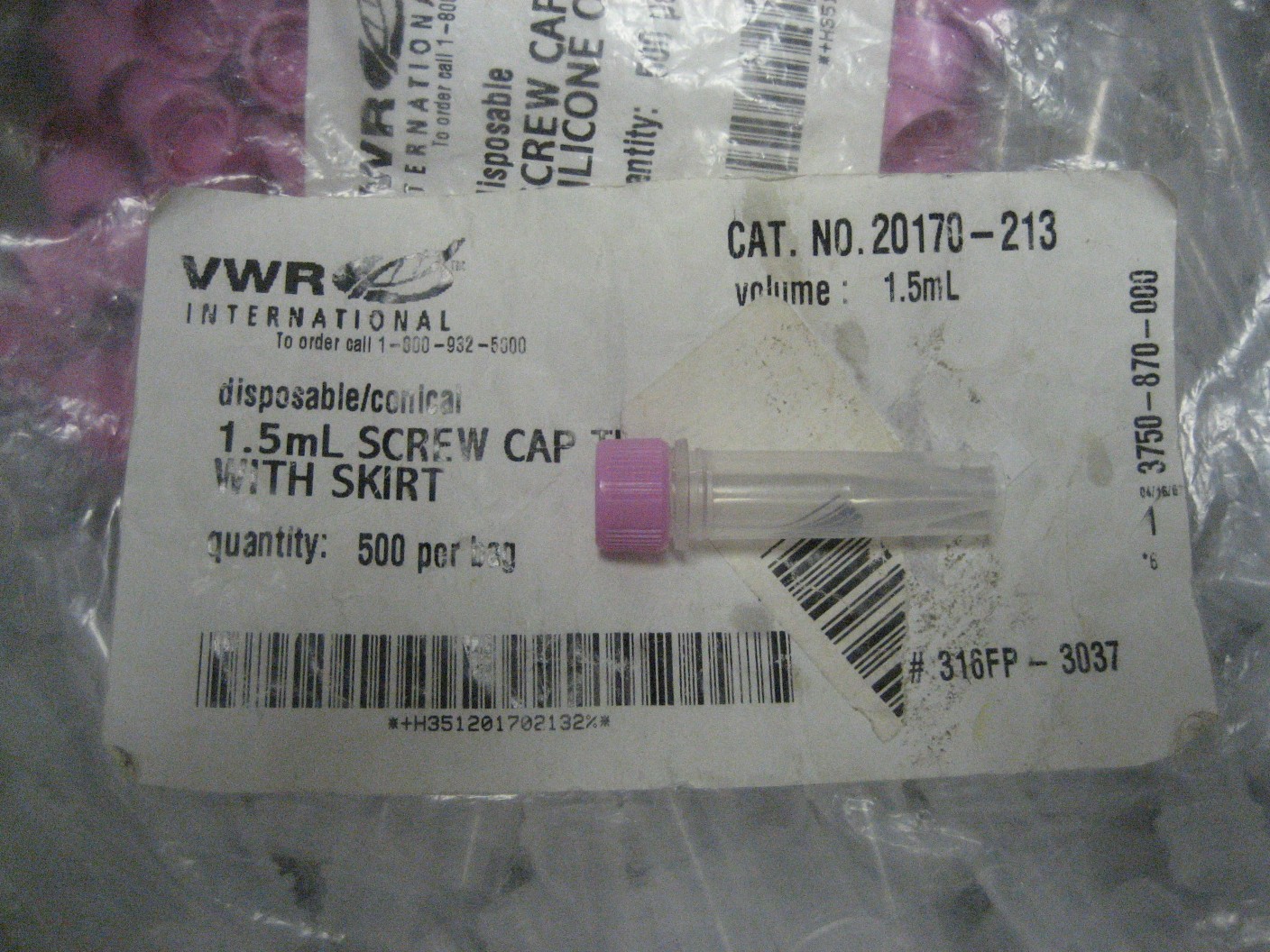

| Image | Vendor | Model | Size | Material, body | Material, cap | O-ring | Skirt? | Rounded? | Description | Notes |

|---|---|---|---|---|---|---|---|---|---|---|

| VWR | 20170-213 | 1.5 mL | PP? | Pink | Y | Y | N | SCREW CAP TOP WITH SKIRT | Retail: looks to be about $144/1000 (includes cap) eBay 2012?: paid about 30 for a mostly full bag Has o-ring |

| AGILENT TECHNOLOGIES | 5188-5251 | 1.5 mL | Y | N | N | MICRO TUBE, SCREW TOP | 2015?: liberated from noisebridge Retail: $37/100 (includes cap) Not skirted. I tend to prefer skirted |

|||

| ? | ? | 1.5 mL | PP | N/A | N | N | N | Primary tube in use Security lock: lid snaps on very securely eBay 2014: 500 / bag, $15 shipped |

||

| Savillex | 200-915-50 600-011-83 | 1.5 mL | PFA | PFA | N | N | N | Link 2018 new: $8.30 *each* I was getting these for WFNA work, but found that polypropylene is actually fine, despite compatibility chart notes |

||

| Lion International | MC01050 | 5 mL | PP | N/A | N | N | Y | Used for medium dies | |

| JIUWU | 5 mL | “Plastic” | N/A | N | DIY Crafts India 221 | |||||

| Corning | CentriStar | 15 mL | PP | Orange | N | N | N | Use for storing bulk dies, like from RAM eBay 2014: $14 shipped for 25 |

|

| Biologix | 50 mL | PP | PVC? | N | N | N | eBay 2010: $5 / 50 Use as temp storage when working (individual dies, decapped DIPs) Use for measuring chemicals |

| Image | Vendor | Model | Tube size(s) | Tube count | Material | Description | Notes |

|---|---|---|---|---|---|---|---|

| Custom? | Custom? | 50 mL | 25 | Polypropylene? White | mcmaster: really like these Heavy duty eBay 2014: 6 for $90 shipped Difficult to knock over |

||

| ? | 10/15 mL: 30 50 mL: 20 | Polypropylene Orange | Snaps together 2013: $10 shipped Light, but usually gets the job done |

||||

| PUL FACTORY | PUL13007 | 5 mL | 32 | Polypropylene White + blue | Link Putting the rack in the lid to put into ultrasound |

||

| Karter Scientific? | 235I2? | 0.5 mL 1.5 mL | Polypropylene? Multicolor | mcmaster: really like these eBay? Can't find purchase notes PAT NO D-359,126 |

Membrane box

Above: a couple of different styles

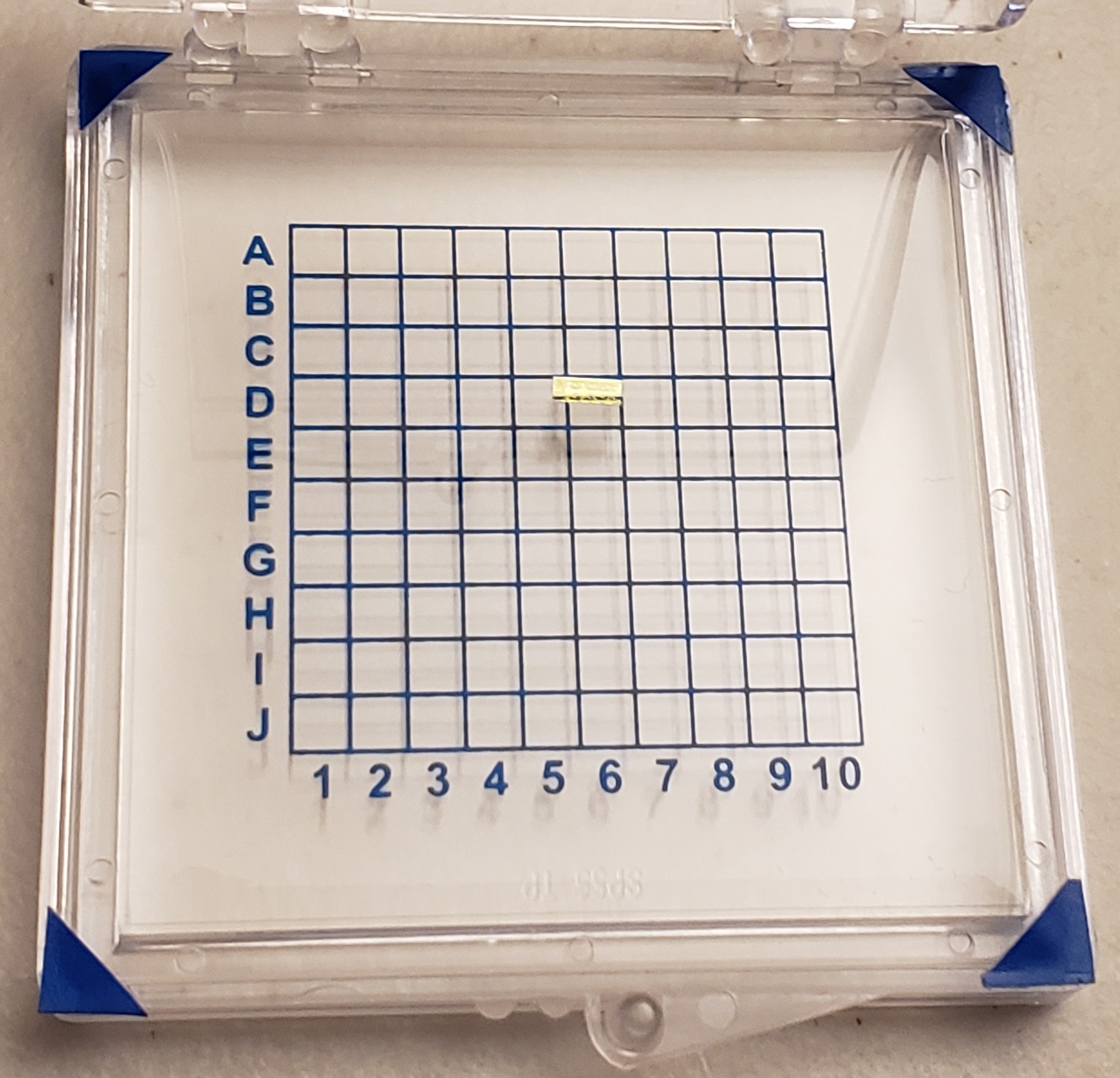

These containers suspend a sample in the center between one or more thin films. Mechanically they work especially well for decapped SMD parts, although ESD boxes usually work well enough. However, they have strong static clean, which is probably bad for ESD.

Links:

eBay RKE

Mine was sold on eBay as “Hinged Display Boxes Elastic Membrane Various Sizes for Optics, Fragile Items” with prices as follows:

- Small (1×1”): $3

- Medium (2×2“): $5

- Large: (3×3”): $10

Material listed as Acrylic. Ones on Amazon are listed as “Material: PS” (polystyrene), but may be a different model.

The hinge is hard to open/close. Unfortunately they don't fit tightly, so its not possible to remove the hinge and friction fit them instead. I wouldn't get these for something you plan to regularly open.

Brand 2

Unknown origin. No branding on them. Unclear why the bottom film is milky but the top is clear. Maybe just to indicate top / bottom?

These are gently friction fit. I was able to open / close them easily, although I did accidentally remove the membrane by once instead of opening it. I'd prefer these to the RKE units.

Waffle pack

Above: different size trays showing typical packaging and stacking

Aka “IC tray”

These are used for dense die storage and are typically stackable. I think vacuum tools are recommended to move dies in and out. I usually use a small bit of tape if I don't care about damaging the dies. or tweezers if there is enough room.

Gel box

Gel boxes are common in the electronics industry for dense die storage. However I don't like them because 1) I've had issues with large dies sticking and breaking when removing 2) you need to index the dies externally to indicate what they are.

ESD box

mcmaster: for decapped large packages (ex: PGA) I use CCI Pillowstat containers (example)

Wafer

Wafers should be stored in standard wafer cassettes. Polypropylene units can be found fairly inexpensive on eBay (ie don't go nuts and buy a PFA cassette since it may cost $200).

Cassette / carrier

Most common form for holding bulk wafers for transport. Entegris/Fluoroware seems to be a popular brand.

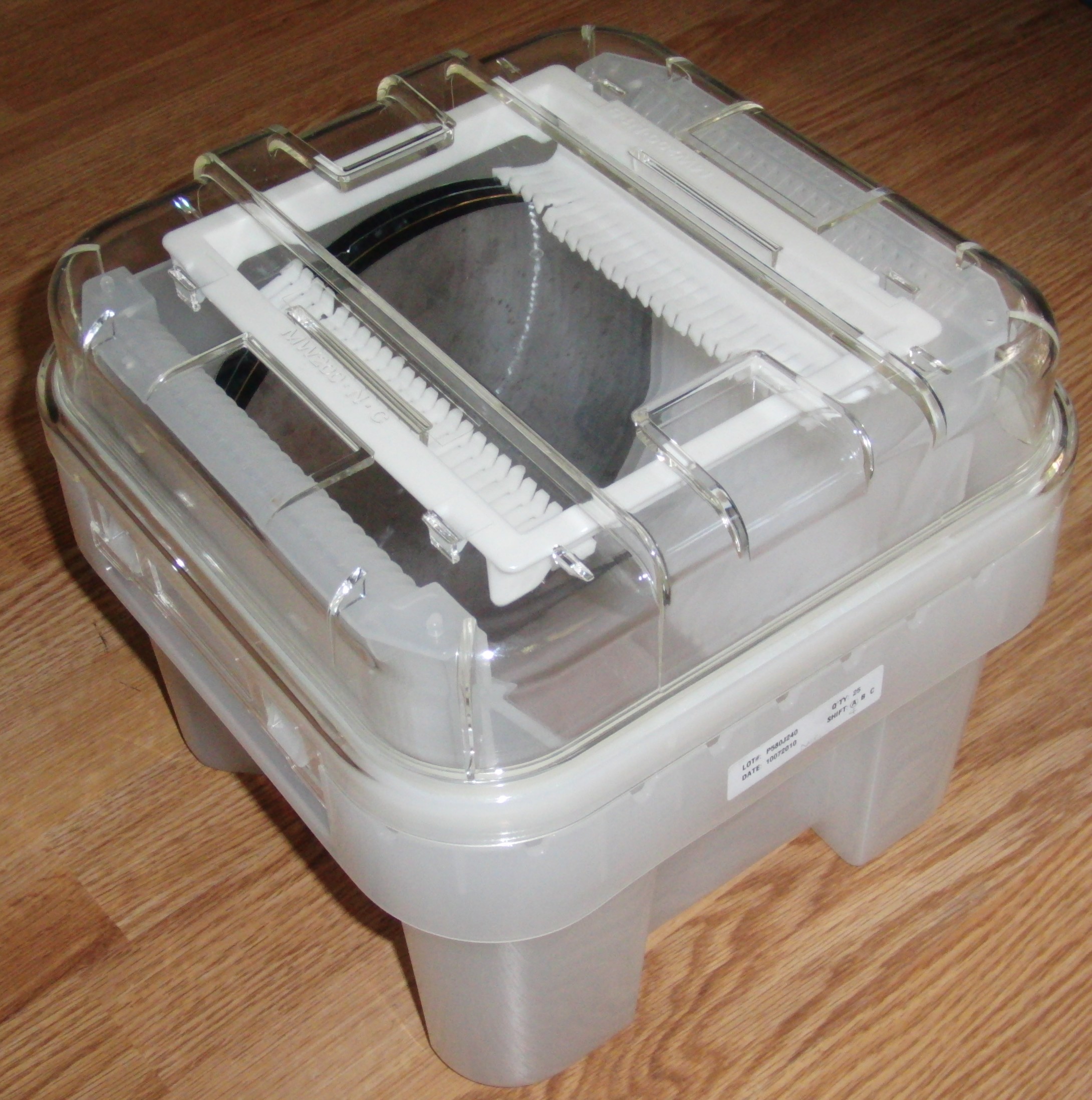

Above: 6“ simple polypropylene Entegris ULTRAPAK 150mm carrier with wafers. Three pieces: box top, box bottom, and wafer carrier. Also if you look closely you'll notice that I have more than one wafer per slot…don't do that for wafers you care about. I have extra blank wafers that I was either going to throw away or stack up.

Above: Shin-Etsu Polymer Co., Ltd. MW200-N 200mm with wafers, a more complex device for holding 8” wafers. Same basic parts as previous but wafers are now spring loaded instead of held in place by the box itself and there is a gasket ring to keep it sealed better. Looks like a few different materials were used as well instead of being uniform PP.

Fabs use special robotic types depending on the technology. 6“ typically use Smif interface while 8” uses FOUP.

Boat

Used for temporary storage. Fused silica boats are used to anneal wafers.

Twist lock

Most common form for holding small quantities of wafers for transport. Above: Fluroware H22-30 4“ single wafer twist lock carrier.

Blue tape

Diced wafers are usually on blue tape. Thin plastic films should stick easily to seal it up. I've been cutting the edges off to make them non-sticky and putting them in standard wafer carriers.

Vacuum pack

I've seen some wafers vacuum packed but presumably only when used for display. A good example are the “Intel: Journey inside the computer” kit wafers.

Mask

Above: Fluoroware H92-500IPW mask holder with mask. Note the nub in each corner so that only the side of the mask is touched.

Foams

Brands

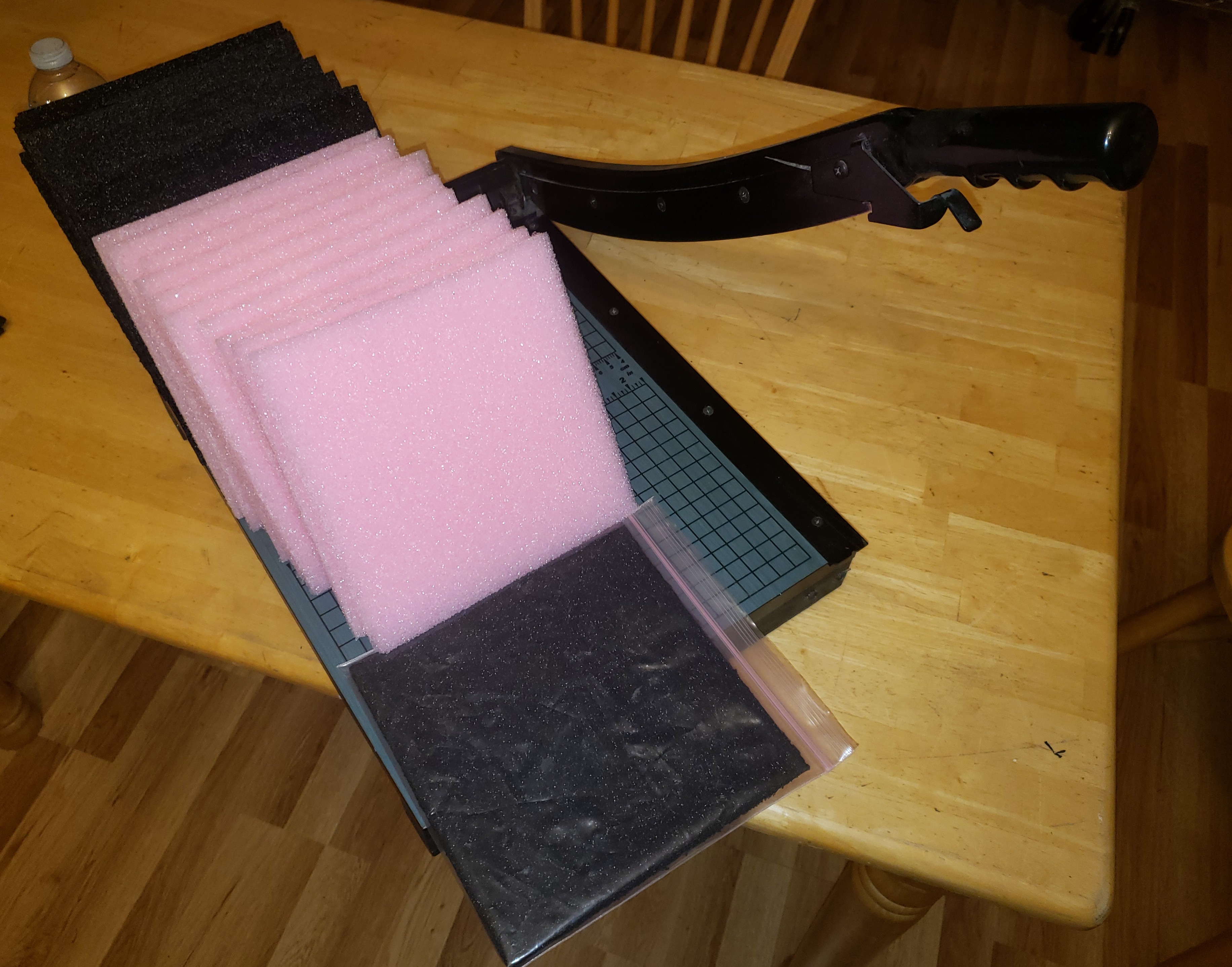

| Image | Vendor | Model | Size | Cell | Density lb/ft3 | Tensile Strength PSI | Color | mcmaster bag | mcmaster bag each | mcmaster bag lg | mcmaster bag lg each | DIP usable? | Notes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| All-Spec | 713-2935 | 3/8 x 29 x 35” | Closed | 50kg/m³ | 515KPa | Black | Cut: 7-1/2 | $33.60/(3*4) $2.80/sht | Cut ~8.5 | $33.60/(3*4) $2.80/sht | Yes | “Non-staining, non-corrosive” “Closed cell - non-absorbent” |

|

| All-Spec | 750-2436 | 1/2 x 24 x 36“ | Closed | 1.8 pcf (28.8 kg/m3) | 31 PSI (215kPa) | Pink | Cut: 7-5/8 | $17.61/(3*4) $1.47/sht | Cut ~8.5 | $17.61/(2*4) $2.20/sht | Yes | Ethafoam 180 as | |

| Zoro | G1112921 | 3/8 x 36 x 36” | Open | 1.4 lbs. cu. ft | 13 PSI | Pink | N/A | No: too soft | |||||

| eBay | 1/2“ x 15.5” x 11.75“ | $1.30/(2*1) $0.65/sht | Cut 9-5/8 | $1.30/(1*1) $1.30/sht |

3/8” (10 mm) thick seems to work well for putting DIPs on both sides. However, 1/2“ (12mm) was easier to source at the time

mcmaster bags: U-Line S-3704 (pink, 8×8”). Fits nicely into divided boxes.

Degradation

This section was added to try to learn why some black conductive foams degrade into powder and others degrade into a (mildly corrosive?) sticky mess

depends on whether you want your foam to turn to goo or powder. personally i prefer goo powder is open cell foam, it works as an abrasive too goo is closed cell foam, which is oddly slick after 20 years the foams disintegrate open cell foam turns into some sort of acid (acetic?) which will eat chip legs i think i don't know about closed cell i think closed cell disintegrates much slower but gets 'sticky'

[Lord_Nightmware IIRC]

The open cell foam is very likely polyurethane foam†, which degrades into a powder (clumps if compressed) primarily via hydrolysis / photo-oxidation depending on the type¹ and (assuming polyester-based PU) releases mainly adipic acid, which is corrosive². †) general consideration of properties, and a few very rough tests such as: heating (chars: thermoset polymer), comparison against known PU foam; with supportive results. https://sci-hub.tw/10.1016/j.chroma.2011.05.013 https://sci-hub.tw/10.2307/20619421

Repairing: mcmaster cleans up pins using glass fiber brush then briefly soaks in HCl. Finally, use liquid tin to re-plate

Conductivity

Terms [Foam vs]:

- Conductive: surface resistance < 1 x 10 5 ohms/square

- Dissipative: 1 x 10 5 ohms/square < surface resistance < 1 x10 11 ohms/square

- Insulative: surface resistance > 1 x 10 12 ohms/square

- Anti-static: inhibits triboelectric charging, “the buildup of an electric charge by the rubbing or contact with another material”

Typically ESD bags are aluminum coated mylar. Pink bags are dissipative, while blue bags offer no protection, but don't generate static. Do foams carry the same convention?

Pink foam

Also seen in the form of bags and packing bubbles.

Alternatives are available, but seems to typically contain amines either coated on the surface or injected into the material to make them static dissipative. In either case that means that it forms a sort of oily coat that can degrade over time as well as coat the product. For example, you should never use pink foam for optical assemblies. Over time this builds up (“blooms”) which makes affixing labels to the surface difficult. A sample product has one year shelf life. [Anti-Static Poly Bags]

Seems that EPE (Expanded Polyethylene) is most common material

Types [Foam materials]:

- EPS (Expanded Polystyrene)

- “most resistant to moisture absorption”

- “acceptable for cold storage applications”

- “resistant to virtually all aqueous media including dilute acids and alkalis, as well as water-soluble alcohols and silicones”

- “limited resistance to paraffin oil, vegetable oils, diesel fuel, and Vaseline”

- EPP (Expanded Polypropylene)

- “excellent energy absorption”

- “excellent recoverability from repeated shocks and deformations”

- “retain their high degree of dimensional stability when exposed to temperature extremes”

- EPE (Expanded Polyethylene)

- “can withstand repetitive deformations and still maintain its dimensions and cushioning ability”

Blue foam

Like above, but less sensitive to moisture [Why pink]. Unclear if it has any disadvantages (cost, lifetime, etc)

Black foam

From private communication (speculative but may be good lead):

- Crosslinked type

- probably lasts longer but it decays into goo

- Non-crosslinked

- lasts shorter and decays into powder

- how long each one lasts depends on manufacturer, amount of ozone/uv exposure, etc

Some foam is firm and is probably the type that decays into powder. Other is squishy and is possibly the type that decays into goo. This is density of the same foam type or a way to tell the crosslinking? In either case unclear what it means

Maybe could UV irradiate foam to simulate aging

Density

Vendors talk about low and high density foams. There doesn't seem to be any agreement whatsoever as to what these mean, even within the same vendors. Look at the kg/m3 ratings I guess if you care about density

Blowing agent

In order to turn a liquid into a foam, you need a way to aerate it. Looks like traditionally this was done with CFCs but looks like it may now typically be done with nitrogen.

Label

DIP14 (0.3“)

- 6 mm

- 9 pt

DIP28 (0.5”)

- 12 mm

- 9 pt

DIP40 (0.5“)

- 12 mm

- 5.0”

- 9 pt

References

- Foam materials: http://www.efpcorp.com/material-info.cfm

- Anti-Static Poly Bags: http://www.millerpolybags.com/anti-static-poly-bags-c-582_512_517-l-en.html