Table of Contents

Description

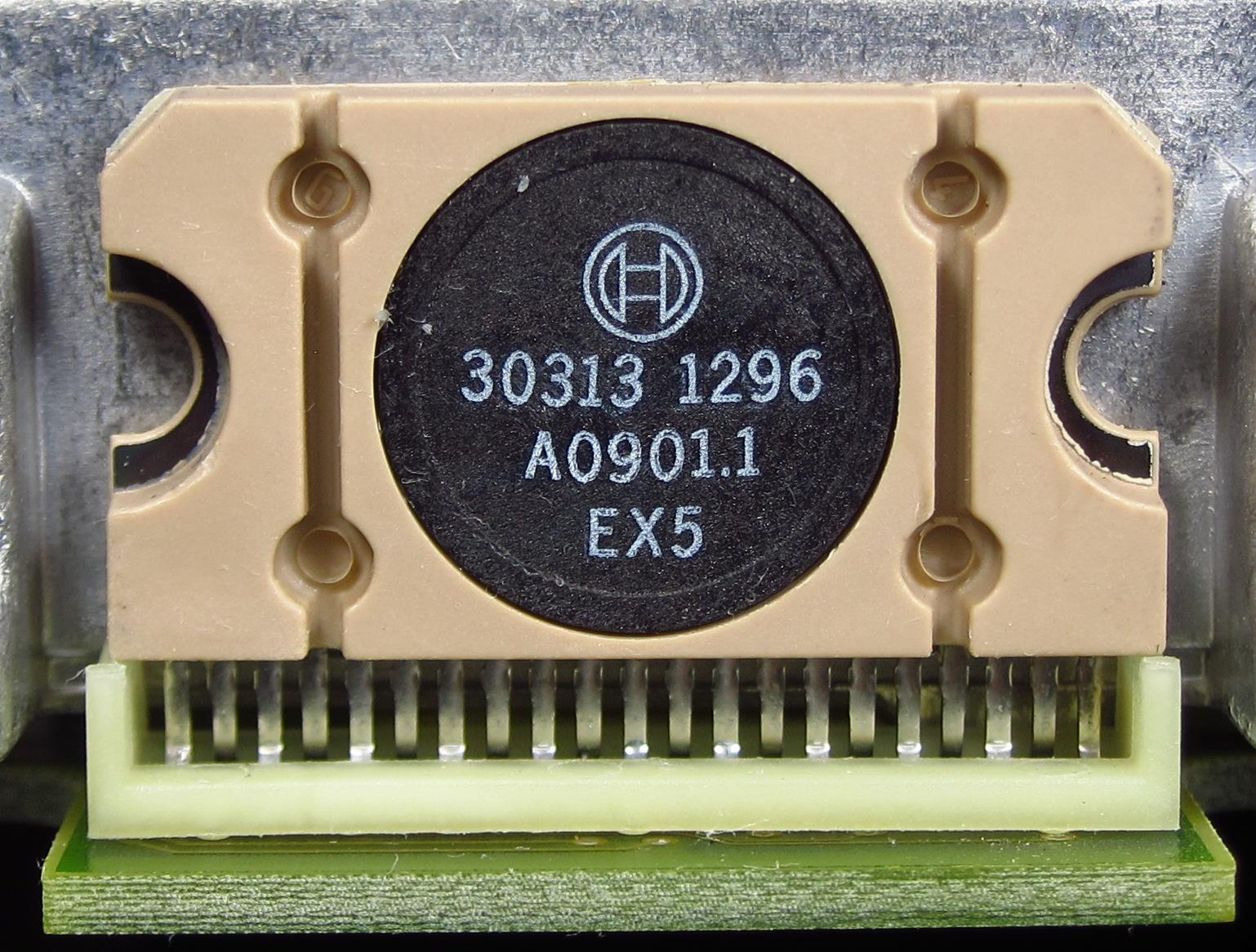

This part was taken from a Motronic M1.7.3 engine control unit (ECU), which was commonly used on 1.6L & 1.8L 4-cylinder BMWs of the mid-E36 generation. While this chip was likely used on a number of ECUs, the specific one in this case had Bosch PN 0 261 203 661.

Functionally, this chip is a 6 element array low-side switching mid-current drivers. Depending on the Motronic version, there are usually 2 or 3 of these present on the board. They switch most of the power relays, evaporative emissions purge valves, idle control valves, the “Check Engine” light and other things. Also, notably, one of these 6-channel arrays is typically dedicated to firing the fuel injectors. In the Motronic 1.x family, there are 2 injector control channels, so the drivers used for those have two pairs of 2 or 3 outputs tied together.

This device is more than just a basic current switcher. It also provides feedback in a couple of ways depending on how pins 15 & 16 are connected (full understanding TBD).

- One method uses the TTL input pins, and they latch high when the output for a given channel sinks >~2mA. The MCU in the ECU is a SAB80C515, so it will latch a logic-low pulse on the desired GPIO pin, which sets a channel in the b30313 active. If that channel sinks the required current, it will pull its input pin high for some number of microseconds, which overrides the weak pull-downs on the MCU's GPIO pin. The MCU can then read the physical port logic level to determine if a load was connected. This is how the ECU is able to determine if there is a fault in the wiring or the device and provide a diagnostic code. This mode is used for all loads except the fuel injectors.

- The other feedback method, which is still being analyzed, does not seem to latch the inputs. This mode looks for a current of >600mA to be sunk (total, this applies to the fuel injector channels which are pairs of 2 or 3 outputs tied together). When the requisite current is sunk, a high pulse appears on pins 15 & 16.

Package

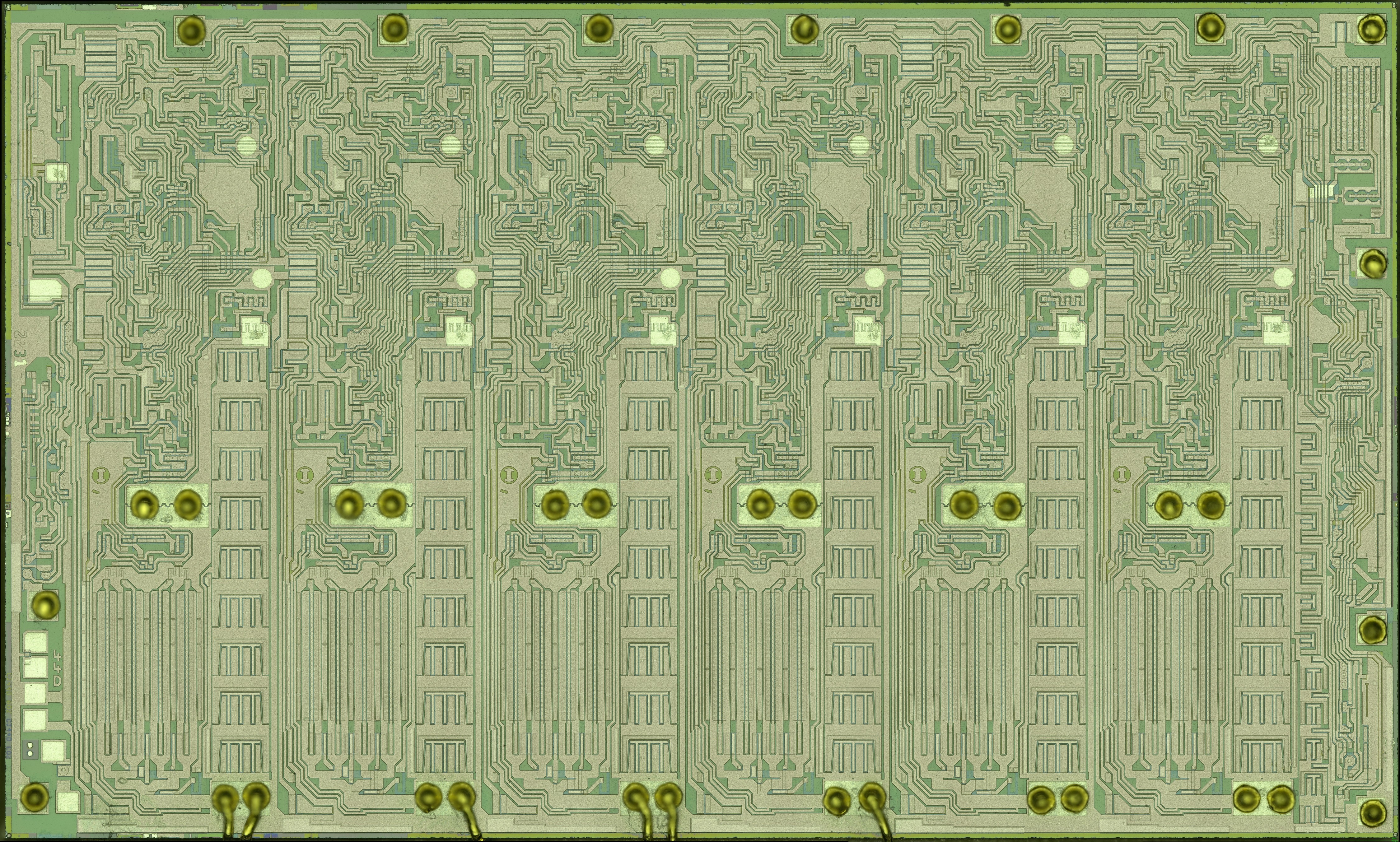

Die

Decap Steps: Popped plastic cover off Used various abrasives on 8" cross-section grinder to remove surrounding packaging Used MEK and a spudger to scrape off the transparent encapsulation over the die Capture Details: Imaging device: Keyence VHX-2000 Magnification: 500X Markings: CJ440 (likely a reference to the commercial PN used by Bosch)

Note: This is a ~16X downsampled version of the original image. A full resolution version (46MB) can be provided. On the to-do list…