Table of Contents

This is more things I tried than a firm recommendation, take what you will out of it. Any e-mails related to explosives won't be honored with an answer.

First steps

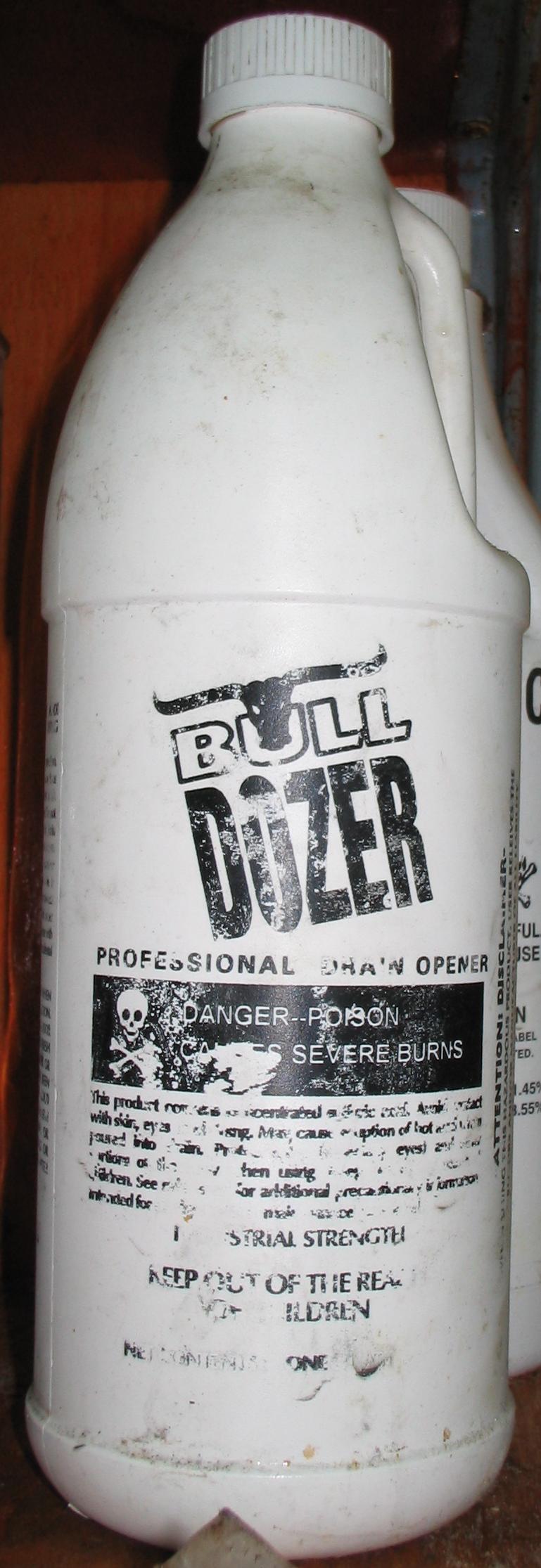

In high school before I got good at ordering things online and such I managed to acquire a vacuum flask, some Bull Dozer brand drain cleaner, and some stump out. I added the chemicals to the flask and added a rubber stopper to keep things inside and keep temperature. A plastic acquire hose dripped acid out the side while it was heated with a wok I got at a thrift store. The receiving flask was placed in ice water to help condense and hat some cotton in top to try to slow its escape. It basically formed a crude retort. At the end of the day though, it did work to produce reasonably strong nitric acid.

The acid was unkind to the hose and turned it really hard. However, it did seem to hold up okay. On the other hand, the rubber stopper did not fair so well. Looking back, I should have covered it in aluminum foil which is pretty resistant to nitric acid. I think the above picture was taken much later, sometime during college when I didn't yet have proper distillation equipment but knew better than to use a rubber stopper.

Procedure

This is more of a procedure of desperation, I suggest the RFNA procedure if you are looking for best work to product payoff

Chemicals:

- 90 g KNO3

- 30 mL H2SO4

Equipment:

- 250 mL vacuum flask

- Aquarium tubing to fit onto vacuum flask

- Aluminum foil covered #5 rubber stopper

- Receiving flask / jar

- Ice bath

- Hot plate

Procedure:

- Place receiving flask into ice bath

- Pour KNO3 into vacuum flask

- Add H2SO4 to vacuum flask and slosh it around to roughly mix it

- Place vacuum flask on hot plate

- Heat until bubbling

- Condensate should begin coming over within 20 minutes

- Run until condensate stops coming over at an acceptable rate

Tips:

- Don't let it get higher than half full. If it does, remove / lower heat

- Acid will work its way into the tube/flask vacuum nipple but shouldn't leak

- Don't try to scale this up. If you want to do something bigger use proper jointed glassware

Real distillation (RFNA)

Having learned a little more about chemistry equipment and no longer making minimum wage, I was able to afford some jointed glassware.

Terrible picture (camera was dying) but it gives the idea. The second was a later very similar setup after I got a new camera. A ring stand holds a flask of KNO3 and H2SO4 in an oil bath. A thermometer allows me to check the oil bath temperature. Hot acid fumes go up through a Vigreux condenser and then at the top transfer to a Liebig condenser. The primary reason for using this was that I got it at the MIT flea market for a dollar. The condenser is passively cooled by circulating through an old freezer radiator and pumped by a diaphragm pump I found in the RPI dumpsters. The receiving flask is in an icewater bath.

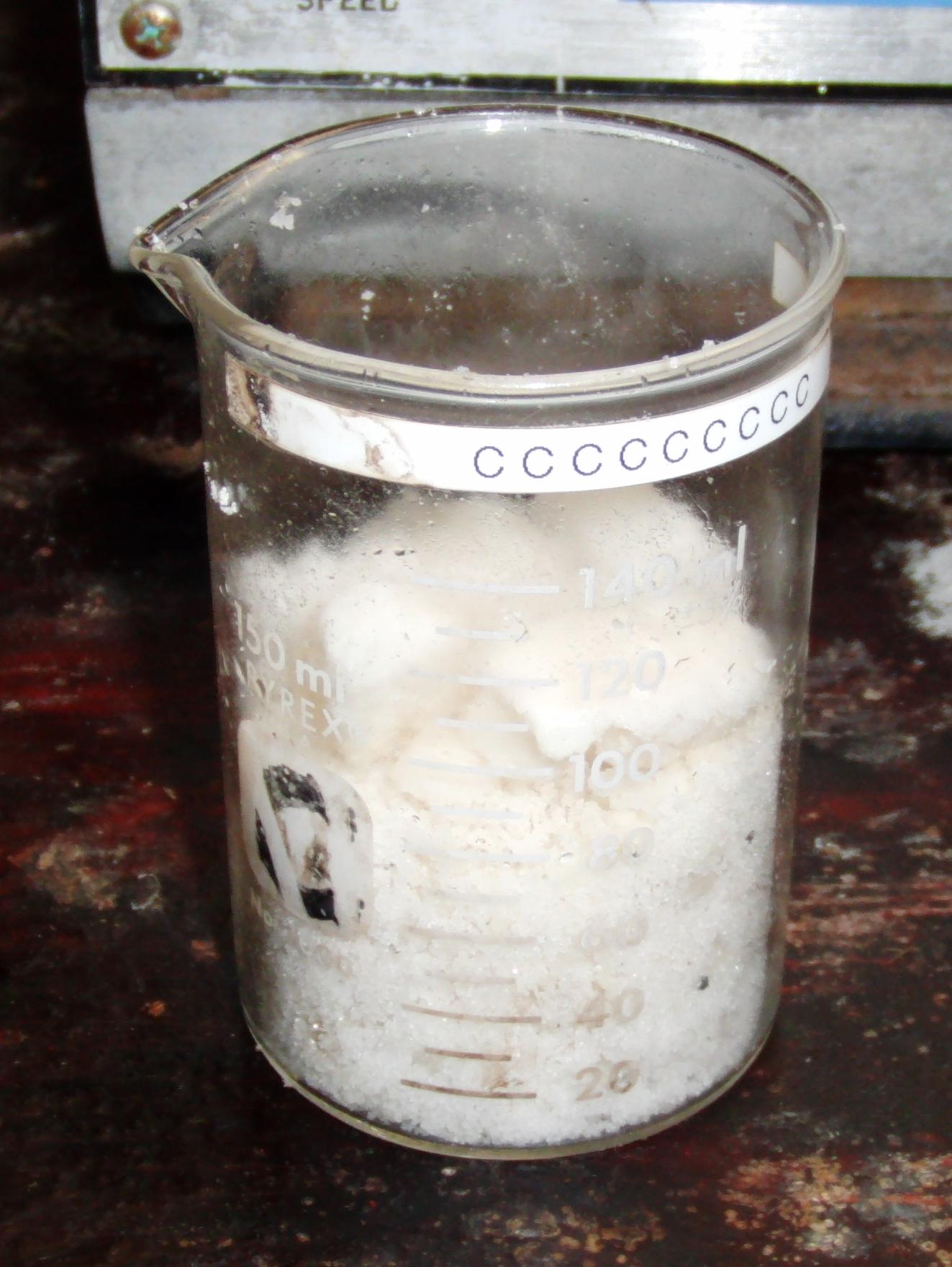

As the KNO3 and H2SO4 are mixed it puts off some NOx (sulfuric reacting with water?). KNO3 sticking to the side will come down soon as vapors begin to rise and condense.

Starting to heat up (from a later run).

Once it gets hot enough the KNO3 will completely dissolve in the H2SO4. It should give a healthy bubble like above. Try not to let the level exceed halfway. Its fine if the mixture is only bubbling at top and is liquid at bottom (ie just at the boiling point).

This works okay but takes a while to heat up (30-45 minutes typical IIRC). Helped a little to put aluminum foil over the still. Overall, the probably was that the Vireux condenser was overkill for the level of purity I require.

Above: also the system got algae when I didn't drain it. Added some bleach and it stopped growing.

Procedure

With my current equipment I'd do something like this.

Chemicals:

- 189 g KNO3

- 50 mL H2SO4 is stoichiometric, I suggest using at least 60 mL if not as high as 75 mL

Above: doubled ingredients for a 1 L flask

Equipment:

- 24/40 500 mL round bottom boiling flask (reactor)

- 24/40 to 14/20 adapter

- 14/20 Liebig condenser

- 14/20 distillation head (connects reactor to condenser)

- Thermometer or plug if no thermometer is available for distillation head. 10/18 is common

- 14/20 right angle vacuum adapter: allows good connection to receiving flask and to drip down and vent excess gas. I haven't tried a straight adapter for a closed system, it might work as well but I am unsure about pressure buildup concerns

- Condenser cooling source (ex: pump + ice water or faucet water)

- Receiving flask. I use 100 mL pear shaped flasks and switch out if/when it becomes full

- Ring stand

- Clamps

- Lab jack

- Heating mantle

Procedure:

- Setup main glassware

- Connect/clamp 14/20-24/40 adapter to distillation head

- Plug distillation head or attach thermometer

- Attach/clamp condenser to distillation head

- NOTE: in picture above the distillation head, condenser, and vacuum adapter are integrated into a single piece

- Start water flowing through the condenser (turn on pump or faucet). Ensure that its not leaking as you don't want water splashing onto hot glassware

- Place receiving flask in ice bath positioned such that it will drip into from the vacuum adapter

- Pour KNO3 into reactor. I find a folded piece of paper or a large funnel works well

- Pour 10 mL at a time of KNO3 into the reactor. Turn it as its poured so that it mixes well. Slosh it around. It will begin to form NO2…don't breath it

- Attach flask to distillation head

- Place heating mantle on lab jack and jack up until the mantle is applying light pressure against the flask. Alternatively stack crap up until its about right like I did in the above pictures

- Heat until bubbling nicely with the flask about half filled with liquid as in above pictures. If heat source is fixed you can adjust heat by moving the heat source (mantle) away from the flask

- Wait until RFNA begins to drip down condenser

- Run while RFNA continues to drips at an acceptable rate

Tips:

- Yields maybe 50 or 60 mL of RFNA

- You can make 70% by adding some water. The H2SO4 will keep water from boiling off and instead favor dilute HNO3. Wikipedia says 70% boils at 121C.

- Use a fume hood if available / do in a well ventilated area. I do this outside and use a 3M full face respirator with acid gas cartridges. I'm looking into building a gas scrubber system, possibly using a catalytic converter

- Use excess H2SO4. The more you use the easier the reactor will be to clean and the less you have to worry about moisture contamination

- Seal all joints. I used PTFE tape on all joints, mostly because it was available from the hardware store. I haven't tried vacuum grease, maybe would get eaten, maybe not

- Probably best not to exceed a 1L flask. At the very least, the self heating must be watched which gets worse as the batch is larger. I'd start with a 500 mL flask

- Depending on ambient temperature, I've had it take as long as 45 before distillate forms

- Initially once distillation comes over expect about 1 drop per second. It will slow down and its up to you what an acceptable rate is before you stop. However, if you use up all the water you should notice that you are getting considerably less than before suddenly. At this point you should stop as otherwise the flask will simply heat up and you'll eventually be boiling H2SO4

- If more than a few mL of acid accumulates in the vacuum trap decrease flow rate or cool collection flask more

- Might be able to put fiberglass or similar in the vacuum trap to help it condense / increase surface area

- Once solution is dissolved / under vacuum do not let it solidify on the surface (its fine if its bubbling on top and slushy under). If you do it will form an insoluble layer that will considerably slow down distillation. Try to rapidly drop pressure (rapidly increase vacuum), in some situations this can shatter it and bring back normal distillation. Thus, if the solution level is getting too high favor decreasing pressure and increasing temperature over simply decreasing vacuum

Losing the oil bath

The next major advancement was switching the oil bath for a heating mantle. While I didn't think it was likely that a flask would break, if it did it would fail catastrophically.

Vacuum distillation (WFNA)

While the above system works it takes a long time to heat up. Vacuum distillation on the other hand quickly draws the fumes forward. Additionally, the pressure regulation allows more accurate flow control and also lowers the working temperature. Also note that I now lab jacks instead of stacking stuff up to put things into position against the ring stand. I have also eliminated the oil bath / hotplate as noted above in favor of a heating mantle and a Variac to control its heat. It works much better and is much safer.

However, I didn't want to damage the vacuum pump so I bought a cold trap. It was cooled by a dry ice acetone bath. This is when it was just poured, the bath freezes over from collecting moisture in the air.

Some people suggested injecting air into the reactor to reduce bumping. I didn't have a problem with bumping and didn't find that it aided the system. More than likely it hurt as drawing in air increases the moisture in the system. The first pictures show the use of a vacuum inlet instead of a thermometer on the distillation head. Part of it can be seen above. It originally had a glass rod in the middle, I guess I removed it and was just playing with pressure regulation by the time that picture was taken.

As the breathing tube wasn't helping it was removed in the next round as seen above. The vacuum inlet is now simply capped off. This worked much better.

Collected distillate. During distillation this is submerged in ice water. The feed to the right runs to the vacuum trap.

The biggest problem with this approach is making sure the vacuum trap stays cool enough. Although it still had some dry ice in it it was no longer iced over and so obviously had risen in temperature. It evidently wasn't cool enough anymore as the pump got NOX in it. I'm not sure if it sustained any noticeable damage, it seems to still work fine.

Procedure

With my current equipment I'd do something like this. Similar to the RFNA procedure with the following modifications

Additional chemicals:

- 10 lbs dry ice. This should allow several batches

- 500 mL acetone or denatured alcohol

Above: doubled ingredients for a 1 L flask

Equipment:

- Tubing between vacuum adapter and cold trap

- Cold trap

- Cold trap container. Dewar is ideal, a beaker will also work but will leak heat

- Tubing between cold trap and pump

- Vacuum valve. I use a Swagelock valve because its stainless is chemically resistant and wedges into the tubing nicely

- Vacuum pump

Procedure:

- Setup vacuum trap

- Place vacuum trap in container

- Pour in acetone until sufficiently covered

- Put dry ice into acetone

- Setup main glassware. Use previous setup and then do the following

- Seal collecting flask to vacuum adapter with PTFE tape

- Start cooling as previously directed

- Connect tubing between vacuum adapter and cold trap. I connect on the shell to avoid freezing in the column, I'm not sure which polarity is technically better

- Open vacuum valve

- Connect vacuum adapter to vacuum valve

- Connect vacuum valve to pump

- Mix ingredients as previously directed and connect reactor

- Turn on vacuum

- Apply heat

- Adjust vacuum as heat increases by adjusting vacuum valve. Try to maintain a healthy bubble as shown earlier. Required heat should be lower than RFNA distillation

Tips:

- Watch vacuum trap temperature. Even if there is dry ice left it might not be cold enough

- Watch pump oil and interior for signs of NOx contamination. Stop if begins to get contaminated

- If / when changing collection flasks close the vacuum valve to let vapor bring the system up from vacuum. The collection flask should then be removable reasonably easily

- Because of the vacuum trap, this should put off little gas while running and really only some when disassembling

Continuously cooled vacuum trap

The dry ice works okay but I wanted to look into alternatives, in part to guarantee the temperature stays low. I decided to try an electrically driven cooler. While NO2 condenses at only 21C, lower temperatures condense things faster / more completely. I found a -100C immersion cryocooler and will be using that for the next batch. I'm out of FNA so it will likely be in the near future. I have some dewar that fits both the cooling head and the vacuum trap meaning the system won't require a pump. I also have a peltier cooler for cooling the condenser.

Admittedly the vacuum pump only cost me $50 (although I think that was a good deal) while the cryocooler cost several hundred…but I like experimenting with different configurations. In other words, if you are strapped for cash, this is not a good approach. Dry ice costs me a few dollars a pound and you might be able to argue that its less expensive to buy old vacuum pumps and just let them burn out (if that's even easy to do so). I've also considered using potassium permanganate in the vacuum trap as its very reactive with NOx and cheap. Activated carbon would work fine as well but I'm not sure it can absorb as much. I'm looking into a catalytic converter as another alternative which could also also help a lot.

Cleaning up

Don't try to pour old the hot H2SO4 / KNO3 biproduct (KHSO4). It will likely solidify on the cooler upper half of the flask and close it off. This can cause pressure to build from the still hot bottom cooking off. Instead, wait until its cool and then add water. It will likely take a number of washings to get it all out. Warm water and sloshing it around so that it breaks up and not just dissolves helps. I blow the flask with a fan to help it cool down faster. The more acid you use the more acid that will be leftover and keeping the mixture liquid. Above: KHSO4 waste product.

References

http://www.sciencemadness.org/talk/viewthread.php?tid=13090&page=2

- Persulfate to reduce NO2