FEATURES

Designed to CAMAC Specifications IEEE

583 and 595

Max. of 62 Crates on Serial Loop

Optional test points on front panel for Clock

and Data

Crate address selection via front panel

switch

Serial clock rates to 5 megabits per second

Bit or Byte Mode of Operation

Asynchronous Demand Generation

Magnetically Shielded Relays

APPLICATIONS

CAMAC Standard Type L-2 Serial Crate

Controller

Large distance between CAMAC crates in

a Serial Loop Configuration

Operations with any standard CAMAC

Serial Driver

Operates in 50 gauss Magnetic Field

Industrial Process Control

|

GENERAL DESCRIPTION

Bi Ra Model 1502 Type L-2 Serial Crate Controller complies fully with

the CAMAC specifications. This double-width module is the CAMAC

standard interface between the CAMAC Serial Highway and the crate

dataway. This Model 1502 will operate with any standard serial driver

(such as the Model 1401) and allows operation with up to 62 crates in

a loop arrangement. The units may be directly cabled or linked with

adapter modules and modems. The units can be operated in the Bit or

Byte serial modes. The Bit serial mode allows for economical cabling

between units, where as the Byte mode is ten times faster in

operation. The units will operate up to 5MHz clock rates; the

transmission medium may limit the maximum clock rate. The use of

fiber optic adapters allow operation over longer distances and higher

speeds than direct cabling between units.

DEMAND MESSAGE OPERATION

Model 1502 will generate demand messages in response to any LAM in

the crate. The three Byte message is inserted between other messages

on the serial highway. The unit will generate Repeat-Demand messages

if the LAM is not cleared in a specified elapsed time. Delays from

msec to ten seconds are switch selectable on the module. The repeat

can be disabled with a strap on the module. The SGL connector is

mounted on the rear of the module above the dataway and is the

standard 2DB52P connector. The connector has all the signals

necessary to operate the unit with the standard auxiliary controllers

and to initiate demand messages.

MODEL 1502 TYPE L-2 SERIAL CRATE CONTROLLER

|

STANDARD INTERNAL FUNCTION CODES (N=30) FOR MODEL 1502 |

NORMAL |

OFFLINE |

BYPASS |

||||

|

COMMANDS |

SQ |

SX |

SQ |

SX |

SQ |

SX |

|

|

Read Status Register |

N30 F1 AO RD2 |

1 |

1 |

1 |

1 |

1 |

0 |

|

Write Status Register |

N30 F17AO WT2 |

1 |

1 |

1 |

1 |

1 |

Q* |

|

Selective Set Status Register |

N30 F19AO SS2 |

1 |

1 |

1 |

1 |

1 |

0 |

|

Selective Clear Status Register |

N30 F23AO SC1 |

1 |

1 |

1 |

1 |

1 |

Q* |

|

Reread Data Field |

N30 FO A1 RD1 |

DSQ |

DSQ |

1 |

1 |

0 |

|

|

Read LAM pattern |

N30 F1A12 RD2 |

1 |

1 |

0 |

0 |

1 |

0 |

|

Dataway command |

Q |

X |

0 |

0 |

1 |

0 |

|

|

Error Reply |

*X=1 for command to clear BYPASS |

0 |

0 |

0 |

0 |

0 |

0 |

STATUS REGISTER ASSIGNMENTS

|

BIT |

Write logic 1 into Register |

Read Logic 1 from Register |

State on Power Up |

|

1 |

Generate Z |

always 0 |

0 |

|

2 |

Generate C |

always 0 |

0 |

|

3 |

Set I=1 |

lout = 1 |

1 |

|

4 |

DERR = 1 |

0 |

|

|

5 |

DSX =1 |

0 |

|

|

6 |

DSQ =1 |

0 |

|

|

7 |

Dataway I = 1 |

0 |

|

|

8 |

Reserved |

always 0 |

0 |

|

9 |

Enable Demands |

Demand Enable |

0 |

|

10 |

Set Internal Demand L24 |

L24 =1 |

0 |

|

11 |

Collapse Loop |

Loop Collapsed |

1 |

|

12 |

Apply Bypass |

always 0 |

1 |

|

13 |

Dataway off line |

Dataway off line |

|

|

14 |

Switch off line |

||

|

15 |

Reserved |

always 0 |

|

|

16 |

Selected LAM present |

LOOP COLLAPSE AND BYPASS

Bits 11 and 12 of the status register control magnetically shielded relays in the SCC. The contacts of these relays control external Loop Collapse and Bypass hardware, via contacts in the D-ports connectors. The state of power-up or when crate power is removal are the same, the loop is not collapsed, and BYPASS has been applied.

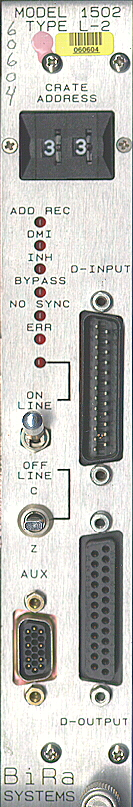

FRONT PANEL CONNECTORS

The front panel serial highway connectors have contacts that allow control of external By-Pass and Loop Collapse devices. If power is lost in the crate, the By-Pass contact will close the Loop Collapse contact will open. The connectors have the standard configuration that allows connecting one serial cable to the OUT connector and installing a jumper connector in the IN connector. The optional auxiliary connector allows front panel access to clocks, Bit data signals, and module voltages.